As a first consideration, foam equipment is classified as either low- or high-pressure, depending on the pressure of the chemicals as they enter the mix chamber or head.

Typical low pressures are 50–200 psi (345–1379 kPa), and high pressures are considered as 1000–3500 psi (6.9–24.1 MPa). Some machines, particularly those used for slab foam production, are hybrid types that use low-pressure pumps on some streams and high pressure on others. The type of machine chosen depends on the foam type, versatility required, foam volume, and employee skills. High-pressure machines require greater technical skills for both operators and maintenance personnel. Independent of the technique used, several common elements are needed for effective foam production:

RAW MATERIAL SUPPLY

Raw material supply includes the delivery containers from the chemical suppliers, in-house storage tanks, blending tanks, and the supply or day tanks for the foam machine. In some cases, a given container may serve two or more purposes. Supplier delivery is from rail cars, tank trucks, rubber bags in trailers, tote bins, or drums. When the delivery is made in large bulk containers, the materials are normally transferred to in-house bulk storage tanks. Handling of the bulk components depends on the chemical requirements, such as the need to maintain temperature or agitation. Isocyanates are stored in moisture-free conditions to prevent undesirable reactions. Some isocyanates also require heating to prevent solidification. For high-output slab stock machines, materials are normally delivered directly from bulk storage to the metering pumps. With other machines, the materials are delivered to intermediate conditioning tanks or day tanks at the foam machine for better maintenance of temperature and material conditioning. The specifics of the day tanks vary with the machine manufacturer and include single- and double-walled tanks with or without internal temperature control coils or plates, insulation, agitators, and means for recirculation. The tanks may also be pressurized or nonpressurized. Construction materials depend on the characteristics of the component, but the tanks are typically carbon steel with inner coatings of phenolic or epoxy if the component is corrosive. Stainless steel tanks are required for specific applications. Automatic fill systems are generally used to ensure proper component conditioning.

METERING UNITS

Metering units may be high- or low-pressure units. Independent of these classifications, the units must deliver and maintain a high degree of accuracy, usually within ±1%. Low-pressure machines are available to handle as many individual components as necessary to meet the formulation requirements, while high-pressure units are typically limited to two or three components, unless special provisions are made. Output capabilities range from a few ounces or milliliters per second for applications such as pour-in-place gaskets, to 1000 lb/min (454 kg/min) or more for large molded parts or slab stock production. With machines that are used for periodic shots, exact material delivery during the shot. With continuous pour machines, recirculation capability may be a needless expense.

Low-pressure Machines

Low-pressure machines normally use high-precision gear pumps. Specially designed pumps are required if abrasive fillers are used in the foam formulation. To eliminate problems that exist with seal leakage and environmental controls, isocyanate pumps are supplied with magnetic drive coupling systems. Various pump drives include direct drive units with DC or variable-frequency AC motors, gear motors, chain drives with replaceable sprockets for output adjustment, gear trains, and power pulley drives. High-output machines may be configured as hybrid machines (with high and low-pressure pumps) for better accuracy in metering the specific components. On slab stock machines, there is the capability for many streams, but all of the streams may not be active concurrently. They are installed to permit quick formulation changes to reduce change time and eliminate waste. With shot machines, the trend is to minimize the number of streams and thereby eliminate problems that occur with on/off operations.

High-pressure Machines

High-pressure machines are frequently called reaction injection molding, reaction impingement mixing (RIM), or high-pressure impingement mixing (HPIM) machines. This terminology, developed during the early 1970s, refers to systems where the component mixing occurs through impingement of the component streams at high pressure without using mechanical stirrers. Another term, liquid injection mixing (LIM), was used for urethanes; however, the term was later trademarked by General Electric for liquid silicone rubber systems. While they are most frequently considered shot machines, RIM machines are also used for continuous pour applications such as laminated rigid foam panel production. There are two types of high-pressure metering: pumps and cylinders. Metering pump systems. This type of pump uses high-precision axial, radial, or in-line piston pumps capable of delivering the pressures required. These are modified versions of pumps that were originally designed for hydraulic oil or fuel service. Because of the close tolerances and construction materials, these pumps are not used with particulate materials that are abrasive, such as glass or mineral fibers. Very high viscosity materials are also not handled successfully, since the pumps have virtually no suction capability and clearances are very small. The nominal maximum viscosity limit of these pumps is 2000 centipoise (cP) at operating temperature. Through the use of booster pumps, higher viscosities are handled.

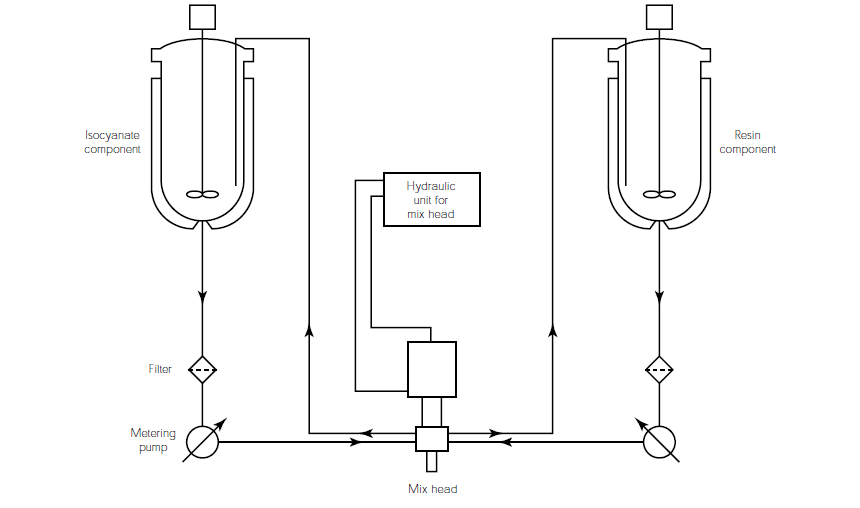

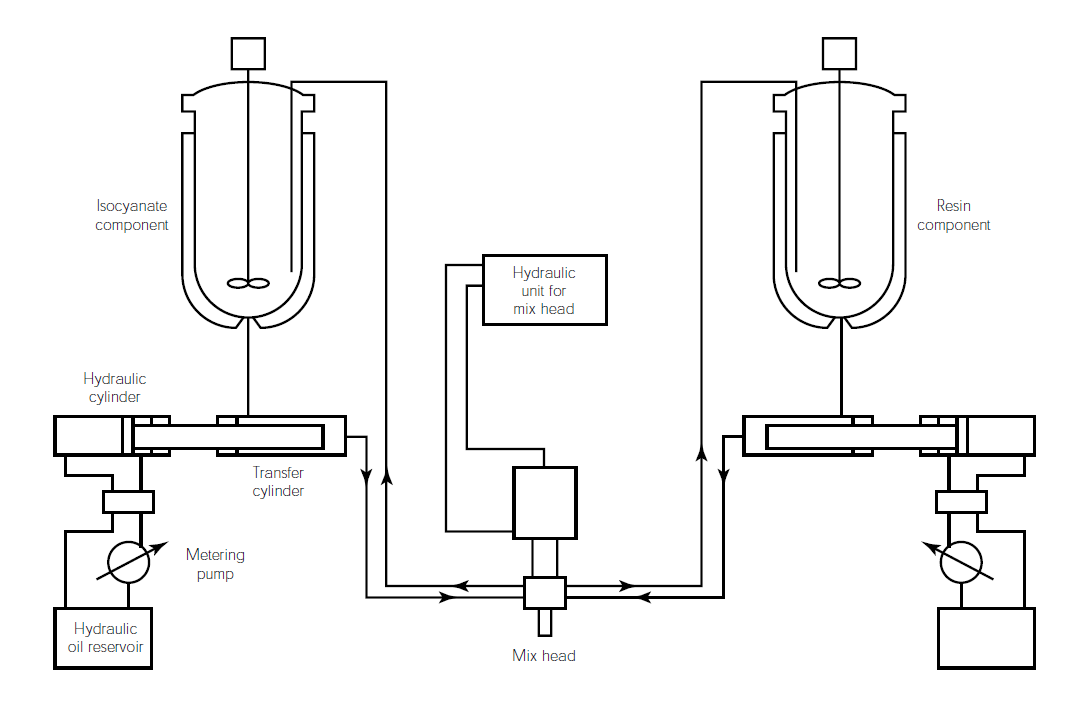

Figure 1

The metering pumps are either fixed or adjustable output types. Various drive systems are used, and output can be varied manually through DC or variable-frequency AC motors, or with servo systems. Figure 1 is a schematic of a high-pressure machine shown with double-wall day tanks for temperature control. Cylinder metering units.

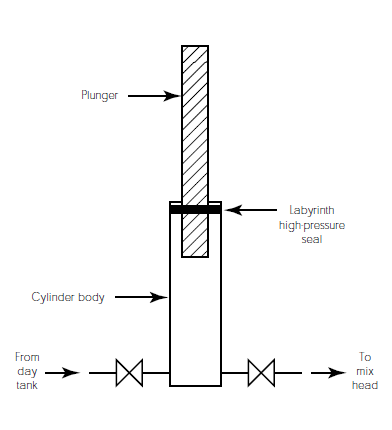

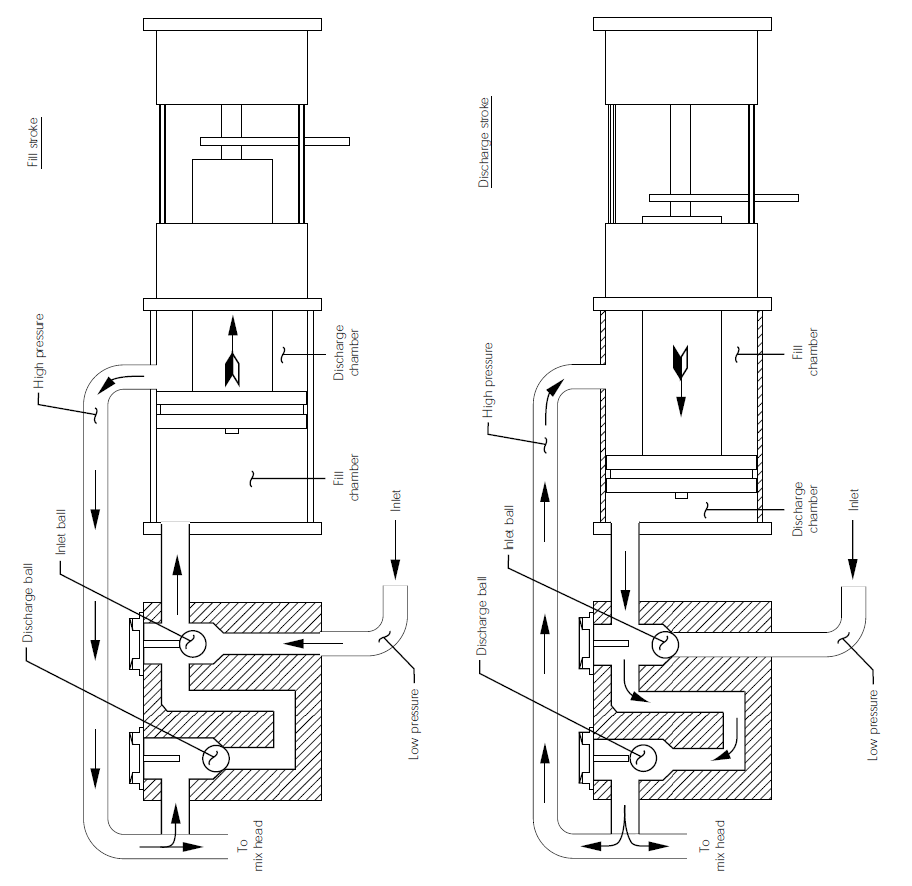

Fig. 2

Designated reinforced RIM (RRIM) machines use lance- or plunger-type cylinders that are capable of handling abrasives and high-viscosity materials. With a lance cylinder, shown in Fig. 2, the moving lance does not contact the inside surface of the cylinder; it only contacts the labyrinth seals so that pressure is developed. The material is displaced, and the cylinder does not empty completely after each lance stroke. Cylinders may be driven independently or with hydraulic slave cylinders.

FOAM EQUIPMENT

Fig. 3.

A schematic of a lance cylinder-type machine is shown in Fig. 3. To reduce the capital cost, a machine may have only a single cylinder to meter the abrasive component while a metering pump handles the nonabrasive component. Although operating pressures for cylinder machines are generally on the same order as metering pumps, special units can deliver impingement pressures up to 15,000 psi (103 MPa) for difficult- to-mix systems.

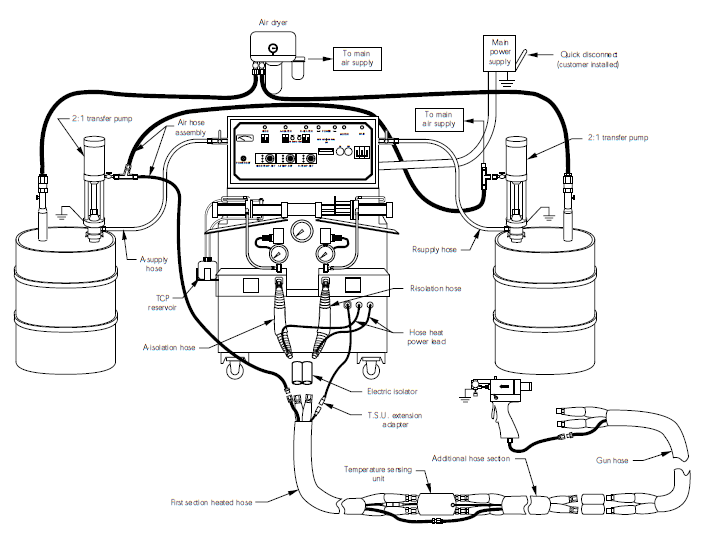

Fig. 4

While cylinder units are usually made to accommodate a fixed shot capability, special units, such as tandem cylinders that are carefully controlled to have overlapping strokes and precise operation of switching valves, are made to permit continuous output. Gusmer-Admiral also offers a continuous cylinder metering unit, the CDC pumping system. This doubleacting cylinder system, shown in Fig. 4, is not a lance cylinder due to the internal piston seal requirement. Other true cylinder metering units are used for special purposes, such as color addition or very low output, where it is difficult to achieve the desired accuracy with a rotating or reciprocating pump. Piston seal wear considerations limit these pumping units to nonabrasive service. Spray foam machines are also cylinder-metering units.

Fig. 5

They are normally driven pneumatically, and the stroke of each cylinder is locked to ensure a constant ratio of materials. Ratios are varied by changing cylinders. Spray units usually have external-mix, selfcleaning, hand-held guns, and the impingement pressures can reach 3500 psi (24 MPa). Valving arrangements are used to ensure essentially continuous flow with these machines. Most spray machines do not have recirculation capability, and components may be warmed by heat-traced hoses to ensure uniform fast reaction of the spray foam; this provides the desired laydown for a smooth surface. A typical pneumatically operated spray unit is shown in Fig. 5. Linden provides a hydraulically powered unit for spray or pour that eliminates problems that can occur if the compressed air supply pressure is inconsistent.

MIX HEADS

Mix heads are classified in two ways: recirculating or nonrecirculating, and low-pressure or high-pressure. In a recirculating head, the components are recirculated from the day tanks through ports in the mix head and back to the tank. The recirculating type with proper temperature control is essential for good operation when foam dispensing is intermittent. While recirculating, back pressure is controlled at the mix head. Spool valves or ports open when the shot is called for. Some continuous pour mix heads also provide some recirculation; however, most are nonrecirculating. With nonrecirculating heads, pumps are started or valving is opened in a sequence that ensures start-up is smooth and losses are minimized. On start-up, the minor streams (catalysts, surfactants, and liquid additives) are turned on first, followed by the polyol and then the isocyanate.