During the continuous production process of slabstock foams, if some basic variables are not properly controlled ...

for instance, ambient temperature, ventilation and humidity on storage, quality of polyols and isocyanates, and so on a thermal oxidation reaction or thermooxidation occurs and can lead to boost fire or burning of the foam. This article explains this type of burning and provides solutions for predicting and preventing it.

Scorching phenomenon

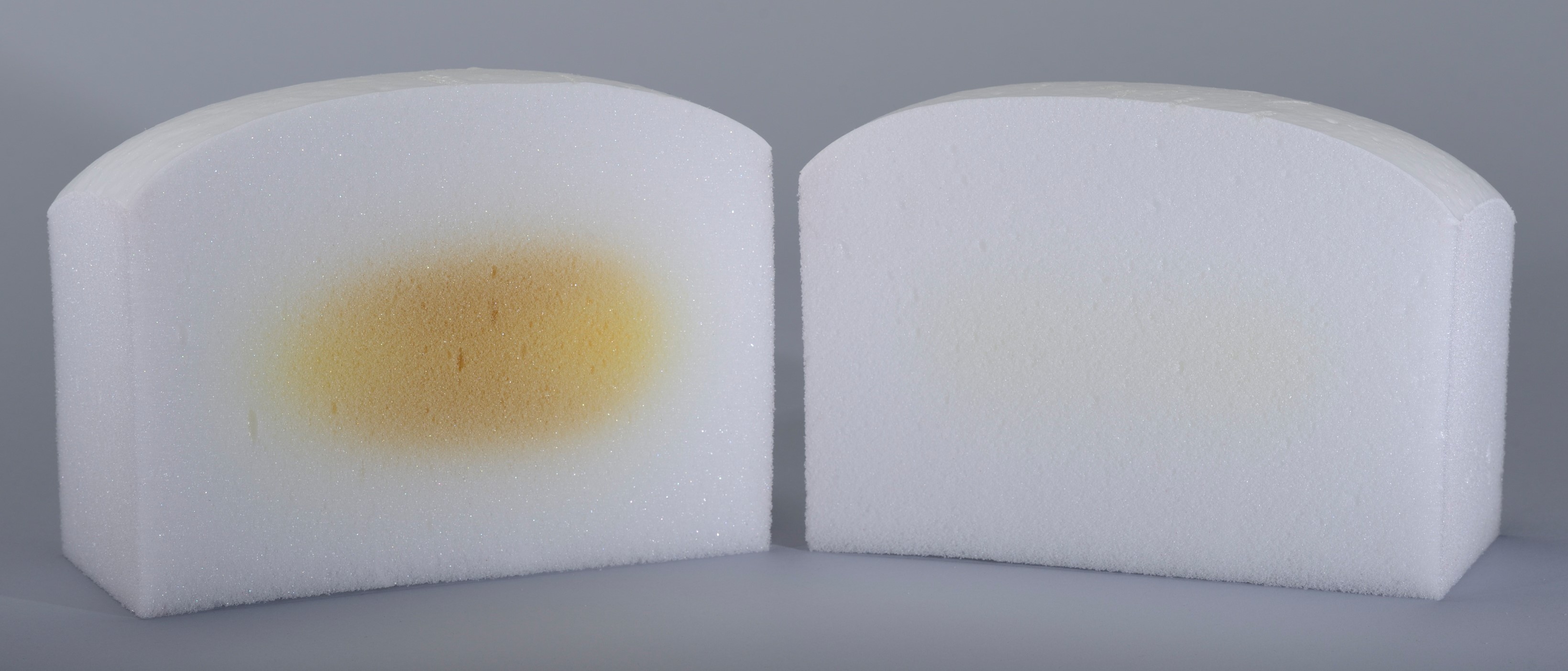

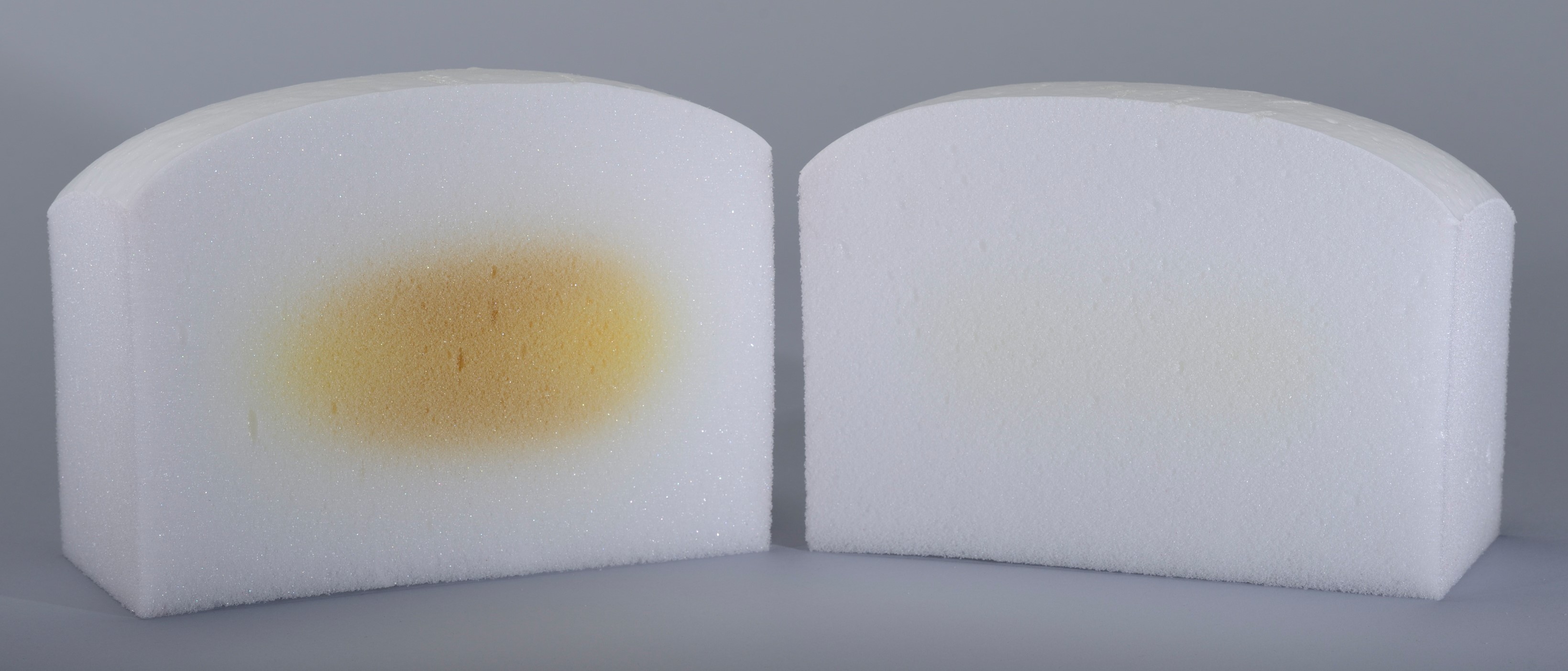

In the fabrication of slabstock polyurethane (PU) foams, due to the very exothermic reaction between isocyanates with polyols and with water, the temperature in the center of the PU bun increases substantially. The PU foams, because of their cellular structure, have a poor thermal conductivity and the reaction heat is not eliminated. As an immediate consequence, the temperature in the center of the bun becomes very high at around 150- 170 °C. At this temperature, the labile polyetheric segment of the PU, in the presence of air, becomes the thermo-oxidative degradation.

The PU foam develops a strong discoloration, more intensive in the center of the bun, representing in fact a region of degraded polymer with poor physico-mechanical properties. This complex phenomenon of darkening and degradation in the center of the bun of slabstock PU foams is called ‘scorching’.

A key factor in the mechanism of scorching is temperature. The severity of scorching depends on several factors, such as the duration and intensity of the heat exposure, the degree of oxidation, and the extent of structural damage to the foam. In severe cases, scorching can lead to the formation of charred residues, which can compromise the foam's physical properties and render it unusable.

Influencing factors on scorching phenomenon in polyurethane foams

Several factors can contribute to the scorching phenomenon in polyurethane foams, including:

- Temperature: The temperature at the core of the foam can increase significantly during the production process, and if it exceeds a certain threshold, it can lead to scorching.

- Humidity: High humidity levels can accelerate the scorching reaction in polyurethane foams.

- Airflow: Poor ventilation or airflow in the storage area can lead to a buildup of heat and humidity, which can increase the risk of scorching.

- Type and quality of raw materials: The quality and type of polyols and isocyanates used in the production process can affect the susceptibility of the foam to scorching.

- Production speed: Faster production speeds can increase the risk of scorching due to the shorter reaction time and less time for the heat to dissipate.

- Foam thickness: Thicker foam blocks can generate more heat and take longer to cool down, increasing the risk of scorching.

Considerations of the ‘Scorching’ Phenomenon

One of the most important methods to determine the thermo-oxidative resistance of a polyurethane material is differential scanning calorimetry (DSC), a small-scale test. The temperature is increased at a rate of 5 °C/minute, between 50-220 °C. The temperature at the beginning of oxidation (strong exotherm) is a measure of the stabilizing efficiency. At a constant temperature increase rate, a high temperature of oxidation at the beginning shows a high stabilizing efficiency and on the contrary a low temperature of oxidation at the beginning shows a poor stabilizing efficiency. One observes that stabilized polyols have higher temperatures for oxidation beginning at around 180-200 °C compared to unsterilized polyether polyol (around 160 °C).

Another DSC test is an isothermal test, carried out at a constant temperature. By maintaining the polyether sample at the specific constant temperature, the oxygen absorption (as a consequence of oxygen consumption in oxidation of the polymeric material) is measured against time. The time needed for oxidation (beginning of oxygen absorption), is a direct measure of the stabilizing efficiency of the polyether [this time is called oxygen absorption induction time (OIT)]. The longer OIT proved a good stabilization.

These DSC methods are indirect methods to determine the scorching resistance of a PU foam resulting from a stabilized polyether polyol, and they are very useful. For example, if the temperature at the start of polyether oxidation (190-200 °C) is higher than the temperature in the center of the bun (160 °C), the PU foam will have good resistance to scorching.

Another method to determine the scorching phenomenon is the determination of the yellowness index of the PU foam, as function of temperature according to ASTM D 1925 test method. A low yellowness index at higher temperatures proved good oxidative resistance and good resistance to scorching.

As mentioned just before, it can be concluded that scorching phenomenon is an undesirable occurrence that must be prevented. It reduces the aesthetic, and hence commercial, value of the foam.

How to avoid scorching phenomenon?

Foam scorching (discoloration) or autoignition is a hazard from the exotherm generated by high-water formulations. To overcome this hazard, rapid cooling systems have to be used for the manufacture of slab stock foams, where cooling chambers are used to pull cool air through the foam to reduce the foam temperature. Depending on the foam machine operation, the foam block may have to be trimmed to ensure that the cool airflows completely through the foam.

Moreover, the presence of some additives (such as phosphorus or halogen-containing compounds added to reduce the risk of foam ignition) can lead to scorching. The use of suitable stabilizers can prevent this undesirable phenomenon. Manufacturers use antioxidant mixtures containing hindered phenols and secondary aromatic amine derivatives to control this occurrence. Other common mixtures for this purpose include other additives such as phenothiazine at low concentrations (30 to 50 ppm). If the concentration of phenothiazine and diphenylamines is high, it can cause a change in the color of polyethers, which is why they are always used in small amounts. The most important antioxidants are phenolic compounds (hindered phenols) with low volatility, which are used simultaneously with certain amounts of diphenylamines or phenothiazine (to observe the synergistic effect).

Hydroquinones have also been used as scorch inhibitors in polyurethane foams, including the addition of halogenated phosphate polyester additives. It has been found that aliphatic phosphites are effective in reducing or eliminating the problem of foam scorching.

It should be noted that the use of antioxidants can partially reduce this problem and prevent color changes in polyurethane foams, but the use of these substances alone is not sufficient to prevent this phenomenon. Anti-scorching agents, along with antioxidants, are used, which include metal salts, organic acids, and epoxy compounds.

In other words, scorching is a complex phenomenon that can result from several factors in the production of polyurethane foams. By implementing appropriate measures to control the factors that contribute to scorching, manufacturers can produce high-quality foams that meet the required specifications and standards.

There are several additives that manufacturers can use to prevent scorching in polyurethane foams. Some common additives include:

- Antioxidants: Antioxidants are compounds that inhibit the oxidation of polyurethane foams caused by heat exposure. They work by suppressing the formation of free radicals, which can initiate the oxidation process.

- Stabilizers: Stabilizers are compounds that improve the thermal stability of polyurethane foams by inhibiting the formation of unstable intermediates during the foaming reaction. They can also help prevent the degradation of the foam's physical properties over time.

- UV inhibitors: UV inhibitors are compounds that protect polyurethane foams from the damaging effects of UV radiation. They work by absorbing or reflecting UV radiation and preventing it from penetrating the foam's surface.

- Flame retardants: Flame retardants are compounds that reduce the flammability of polyurethane foams by inhibiting the combustion process. They work by releasing gases that dilute the oxygen concentration in the foam, making it harder for the foam to burn.

- Fillers: Fillers are materials that are added to polyurethane foams to improve their mechanical properties, such as strength, stiffness, and durability. They can also help prevent scorching by absorbing and dissipating heat, reducing the temperature gradient within the foam.

Manufacturers can use a combination of these additives to optimize the thermal stability and fire resistance of polyurethane foams and prevent scorching. The selection of the appropriate additives depends on the specific application requirements and the processing conditions. It's important to note that the selection and use of additives in polyurethane foam production should be carefully considered, as they can affect not only the performance of the foam but also its cost and environmental impact.

Finally, it can be concluded that scorching is an unwanted phenomenon which can alter the foam’s appearance and even reduce its quality. There are a number of ways that can give us a sight to predict and consequently, prevent the phenomenon. This is primarily dependent on the foam’s chemical formulations and with a suitable modification a high-quality foam can be achieved.